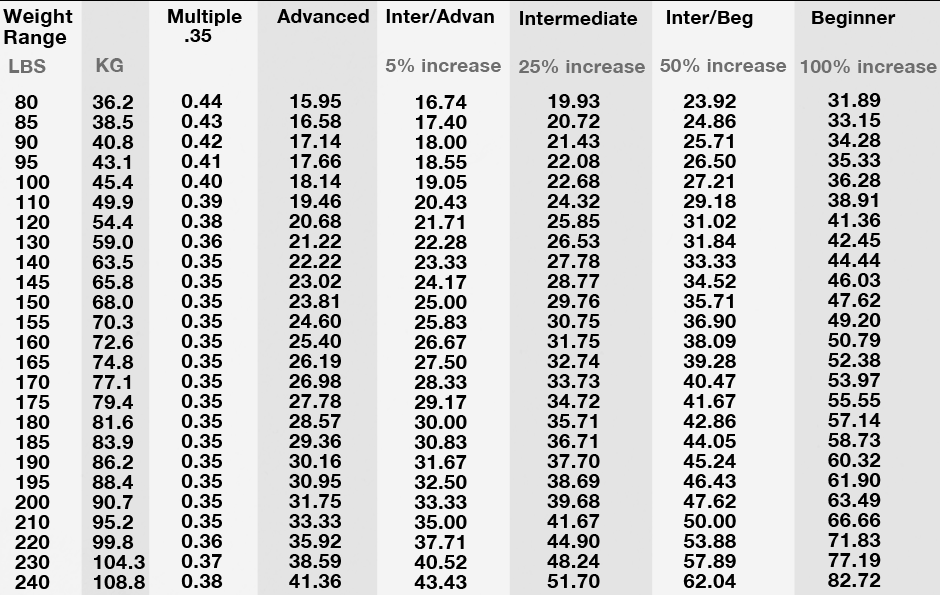

New this year, Miller Surfboards has been using the Shape 3DM CNC. Each board is virtually created on the three-dimensional cad design program. All of my ‘model boards’ are now on file within the system. I Design the board and tweak it within the software to create that magic board for you, the customer. These models have been developed over time through feedback from team riders and individual customers. All my board models can be adjusted in length, width, thickness, rocker, rail shape/volume, and bottom contours. All these aspects dial in and complement each particular surfer’s style. One of the more important aspects of the software is that it assigns a Liter amount for each board file I create. With this liter amount, we can determine exactly how much float a board will have. This information allows me to make a perfect ratio for float to body weight. The liter amount also helps the design process on future boards. It will properly scale up or down a board, maintaining the proper liter float for you. This new direction allows me to further customize the board to the surfer, the type of waves they ride and the direction they want to take their surfing. All customer files are kept on a file so your ‘magic board’ can be identically replicated at any time. This ensures consistency, quality, and quick turnaround for custom boards! All future custom boards and stock boards at Aqua East will have a litter amount assigned on the bottom of each board. Here is a quick reference chart for appropriate liters to reference if the board will be a perfect float match for you!